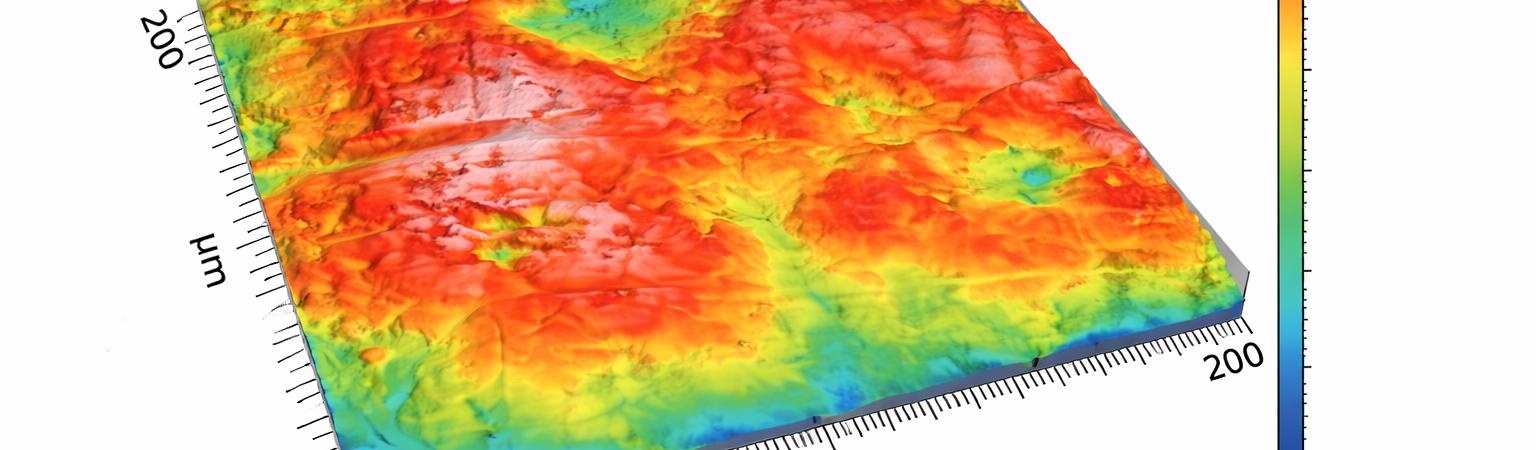

Surface Profiling / Profilometry

To ensure the quality of semiconductor materials, it is essential to characterize them at multiple stages of fabrication and detect defLaser-based profiling measures and maps height variations of just a few nanometers across large surfaces. Oxxius lasers provide the precise wavelength and stability required for these measurements in industrial environments.

Principles of Surface Profilers

A sample surface is illuminated by a monochromatic light beam. The reflected beam is collected and combined with the original beam, creating a stable interference pattern. The presence of dark and bright fringes across the imaged surface depends on relative height differences at each location. As a result, the interference pattern represents the height map of the illuminated area.

However, this approach is limited to height variations smaller than half the illumination wavelength, typically under 300 nm.

Repeating the imaging process using different wavelengths extends this measurement range by more than three orders of magnitude.

Laser requirements & multi-laser configurations

Why are lasers used for Surface Profiling?

Stable interference fringes require a source with long coherence length, an inherent property of laser emission. The performance of a surface profiler depends critically on the characteristics of the illumination lasers:

- The spectral emission line must be narrow and free of strong secondary peaks to generate interference patterns with sufficient contrast. Mode hops degrade image quality.

- The illumination beam must have a well-defined polarization state with a high extinction ratio (PER) to ensure clear interference patterns.

- Lasers must provide precisely defined wavelengths, and those wavelengths must remain stable over time to guarantee measurement accuracy.

- The beam should exhibit a high quality factor and produce uniform illumination across the sample. In some systems, fiber delivery is required to simplify the overall design.

- Adjustable illumination power is preferred to accommodate samples with different reflectivities, and power tuning must not affect wavelength stability.

In practice, laser selection depends on the required height range, measurement precision, and system architecture.

Oxxius DPSS single-frequency lasers

Why choose Oxxius lasers for Profilometry?

Oxxius has developed a unique monolithic cavity technology—protected by more than ten patents—that distinguishes our DPSS lasers from conventional solutions.

- Up to 500 mW through a TEM₀₀ beam with a low (< 1.1) M² value and typical PER exceeding 30 dB

- High spectral purity: the resonator design ensures a spectrum free of detrimental side peaks, with meter-scale coherence lengths enabling high-contrast interference patterns

- A broad selection of precisely defined wavelengths, including 531 nm, 532 nm, 537 nm, and 561 nm (additional wavelengths available on request)

- Ultra-stable output with no mode hops

- Optional fiber-injection module achieving >70% efficiency into a polarization-maintaining fiber

Together, these features ensure that Oxxius DPSS lasers deliver the power, stability, and precision required for demanding profilometry applications.

532 nm narrow-linewidth DPSS laser

Featured product for Surface Profiling: LCX-532S

- Wavelength : 532 nm

- Output power up to 500 mW (continuous wave)

- Coherence length > 300 m

- Wavelength stability ≤ 1pm from one start-up to the next

- Beam quality factor < 1.1

- Operating temperature from 10°C to 50°C

- Power stability < ± 1.0%

The LCX-532S is ideally suited for profilometry, delivering unmatched precision and stability.

Related products

- LCX-531S –single-frequency laser delivering up to 100 mW at 531 nm (TEM₀₀)

- LPX-561S –single-frequency laser delivering up to 500 mW at 561 nm (TEM₀₀)

- L1C-MPA – variable optical attenuator that preserves spectral and power stability

With Oxxius StaxxBeam DPSS lasers, you can rely on a robust illumination source delivering a coherent, stable and high-quality beam, the foundation of precise and reliable profilometry.