Shearography

Shearography is a light-based inspection technique used to reveal flaws and inhomogeneities within bulk materials. Oxxius lasers provide the powerful and stable illumination required for these measurements in industrial environments.

Principles of Shearography

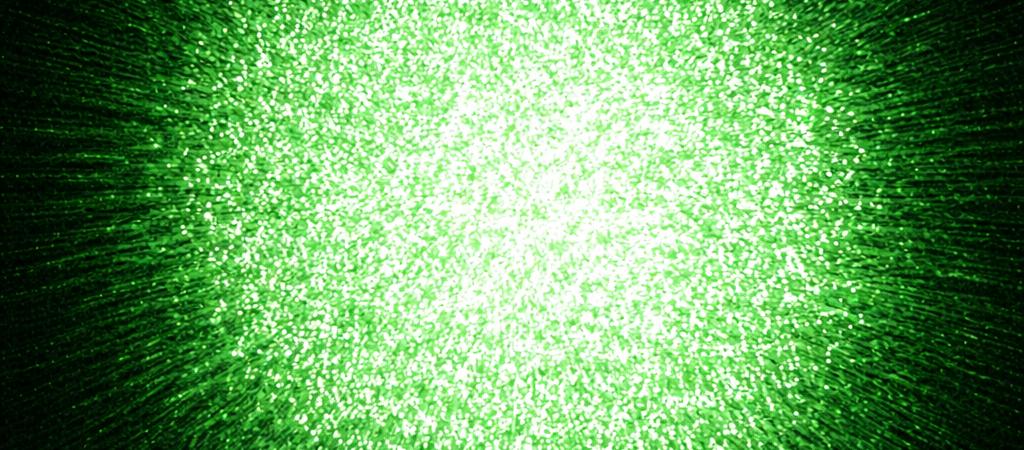

A coherent laser beam illuminates a specimen and is scattered upon contact. This scattered light is collected through an interferometric assembly and processed to extract phase information across the illuminated area. The process is then repeated after the specimen has been subjected to a small amount of strain. Comparing both images (with or without strain) is used to visualize minute surface displacements that indicate latent stress or internal structural irregularities inside the specimen.

Laser requirements

Why are lasers important in shearography?

Shearography relies on interference patterns formed by superimposing the collected light with a shifted version of itself. This requires a light source with a coherence length typically exceeding a few millimeters, which is why lasers are essential. In addition, system performance depends on several other properties:

- High optical power and stability: The illumination must be powerful enough to cover a large field of view, while remaining stable and low-noise throughout the measurement.

- Mechanical robustness: Since the laser source is often integrated into a handheld device, it must withstand shock, vibration, and unregulated temperatures.

- Stable polarization: A well-defined polarization state (high extinction ratio) is needed to generate high-contrast interference fringes.

- Optional beam shaping: In some configurations, a customized beam diameter or non-Gaussian intensity distribution is desirable.

Oxxius DPSS single-frequency lasers

Why choose Oxxius lasers for shearography?

Oxxius has developed a unique monolithic cavity technology, protected by more than ten patents, that sets our DPSS lasers apart.

- Up to 800 mW in a TEM₀₀ beam. This signal is free of mode hops and exhibits a low ratio of optical noise

- Exceptional robustness: No moving parts and no adhesives; our DPSS lasers withstand thermal and mechanical variations.

- A spectrum of high purity: a resonator architecture ensuring a clean spectrum with no detrimental side peaks and meter-long coherence length for stable, high-contrast interference

- Optional beam shaping to deliver a user-defined beam diameter or custom intensity profile

Together, these features ensure that Oxxius DPSS lasers deliver the power, coherence, and stability required for precise shearography.

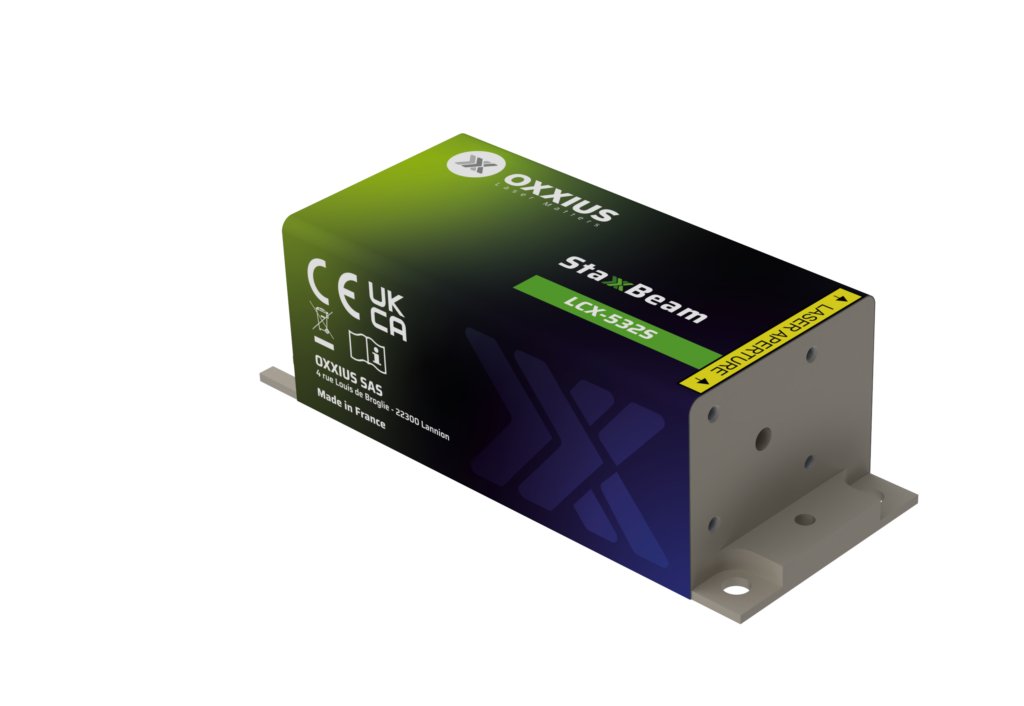

532 nm narrow-linewidth DPSS laser

Featured product for Shearography: LCX-532S

- Wavelength : 532 nm

- Output power up to 800 mW (continuous wave)

- Coherence length > 300 m

- Beam quality factor < 1.1

- Operating temperature from 10°C to 50°C

- Power stability < ± 1.0%

The LCX-532S is ideally suited for shearography, providing exceptional optical performance and long-term stability.

Related products

- LPX-640L – Compact laser delivering up to 1000mW at 640nm (TEM₀₀)

- FC-PM – Accessory for coupling the laser beam into a polarization-maintaining fiber

- L1C-MPA – Accessory for continuous power adjustment

With Oxxius StaxxBeam DPSS lasers, you can rely on a robust, high-quality and stable optical source, an essential foundation for accurate and reliable shearography.