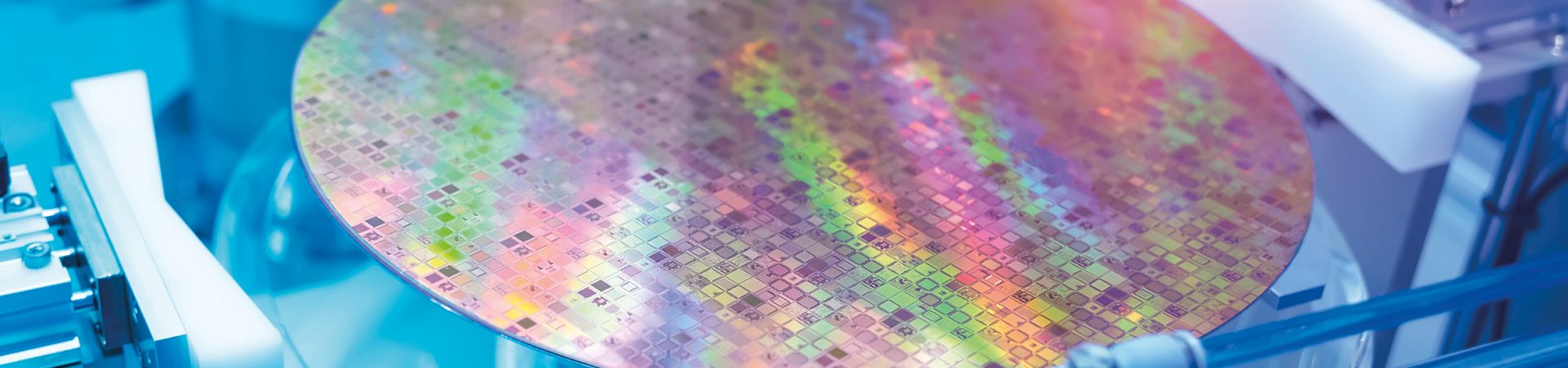

Semiconductor analysis

To ensure the quality of semiconductor materials, it is essential to characterize them at multiple stages of fabrication and detect defects as early as possible. Spectroscopic photoluminescence and Raman spectroscopy are two such methods. Both are contactless, non-destructive, and highly effective for revealing material defects.

Oxxius is a trusted provider of stable, accurate laser sources, essential for carrying out these techniques successfully.

Principles of photoluminescence

How is spectroscopic photoluminescence used for Semiconductor Analysis?

A semiconductor is excited with photons whose energy lies within its absorption band. The material then emits light at a lower energy. Analyzing the emitted spectrum reveals variations in material properties, whether intentional (e.g., doping) or accidental (e.g., defects or impurities).

Laser requirements for Semiconductor Inspection

Why are lasers important for Semiconductor Inspection?

To maximize excitation efficiency and the signal-to-background ratio, lasers must deliver the appropriate excitation wavelength. A high-irradiance beam enables the formation of a small probe spot, essential for high-resolution mapping. Key requirements include:

- A wavelength chosen within the absorption band of the material under study

- Stable output and low optical noise for quantitative and reproducible intensity measurements

- High beam quality (TEM₀₀) to produce a diffraction-limited spot on the sample

- Compact, easy-to-use hardware with minimal maintenance

- Fiber-delivery options (SM, PM, MM) for plug-and-play integration

Multi-line excitation & modular combiners

Why choose Oxxius for Semiconductor Inspection?

Most semiconductor applications require multiple excitation lines to address a variety of materials. Oxxius MixxWave wavelength combiners integrate up to six lasers into a single collinear output, simplifying alignment while preserving beam quality. This flexible architecture scales from a few lines to large multicolor configurations and supports similar imaging techniques, such as fluorescence microscopy.

Oxxius wavelength combiners

Oxxius develops modular, field-configurable combiners spanning the ultraviolet to the near-infrared spectrum. They enable over a billion possible combinations across Oxxius laser families. Options include dual independent channels, fast port switching, power balancing, and AOM-based modulation. Fiber outputs in SM, PM, or MM formats are available to match your microscope or spinning disk system.

Featured product for Semiconductor Inspection

Oxxius MixxWave: up to 6 combined lasers

- Wavelength capacity: up to 6 laser lines co-aligned into a single beam

- Spectral coverage: ultraviolet to near-infrared

(e.g., 375, 405, 445/448, 488, 515/520, 532/561, 594, 633/638/642, 660, 730–785, 1064 nm) - Output power: high per-line power for demanding modalities

- Modularity: independent channels, fast port switching, power balancing across two outputs, AOM integration

- Beam delivery: SM, PM, or MM fibers; free-space delivery also available

Oxxius wavelength portfolio for Semiconductor Inspection

Select the excitation wavelength according to the semiconductor material’s absorption band: 405, 532, 640, 785, 980, 1064 nm.

Combine lines strategically to maximize the signal-to-noise ratio.

Common Oxxius lasers for Semiconductor Inspection

- LBX-405/ LBX-445 (LBX-450) / LBX-473: for photoluminescence over InGaN and similar materials

- LCX-532S: single-frequency DPSS laser as an excitation source Raman spectroscopy

- LBX-785: for photoluminescence of AlGaInP and similar materials

- L1C–MPA: user-adjustable attenuator providing extended dynamic range while preserving spectral and power stabilty

All models emphasize power stability, spectral purity, beam quality, and long-term reliability, with optional fiber-coupling (SM/PM/MM) for rapid integration.

With Oxxius lasers and modular combiners, you gain the wavelength coverage, stability and robustness required for quantitative, multimodal semiconductor inspection, from spectroscopic photoluminescence to Raman microscopy.